Vibration Sensor:

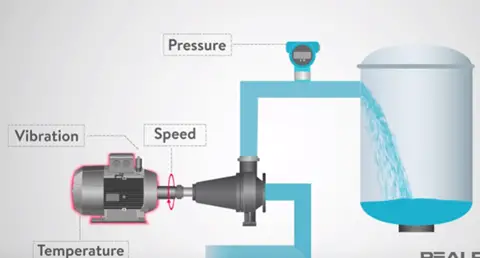

For receiving optimum performance of the machine, it is necessary to monitor the physical parameters such as speed, temperature, pressure and vibration continuously. Negligence in monitoring parameter, may turn on of your machine damage or down time which may results in financial loss. Among these parameters one of the best operating parameter to judge dynamic condition is vibration. In this article, we are going to study about what is vibration sensor, why vibration sensor is required, how to avoid machine failure due to vibration and one case study of over vibration caused 24 MW Power Generator damage.

What is vibration sensor?

Vibration can be defined as mechanical oscillation about equilibrium position of machine or component or simply back and forth motion machine and back component.

Vibration in industrial requirement is sometimes the part of normal operation sometimes it can be sign of trouble. In machine monitoring there are two types of vibration.

- Axial vibration (Thrust)

- Radial vibration

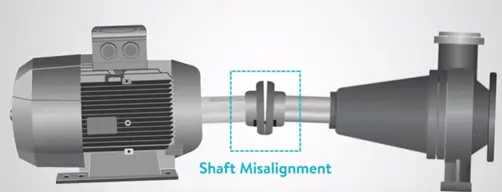

Axial vibration

The axial vibration is a longitudinal shafting vibration is parallel to shaft of the motor. For example shaft misalignment is a axial vibration.

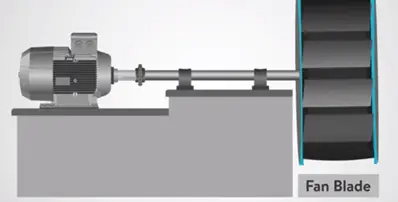

Radial vibration

The radial vibration is occurs a force applied outward from the shaft. The radial vibration occurs from the shafting is heavy parts in the motor it rotates. If there is a formed a fan blade as a fan spins to fan blade will pull outward shaft of the motor causing radial vibration.

Based on the parameter the types of sensors are choosing for the applications.

There are different types of vibration sensors they are.

- Accelerometer

- Strain gauge

- Eddy current

Accelerometer

Accelerometer is the device that measures the vibration or acceleration of motion of a structure. They have transducers to convert mechanical force to cause by vibration or change in motion into an electrical current by using piezoelectric effect.

There are two types of piezoelectric types, they are

- High impedance

- Low impedance

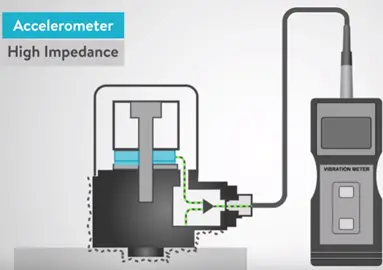

High impedance

The high impedance accelerometer produces an electrical change which is directly connected to the measuring instruments. It requires the special instruments. This is applicable for high temperature applications.

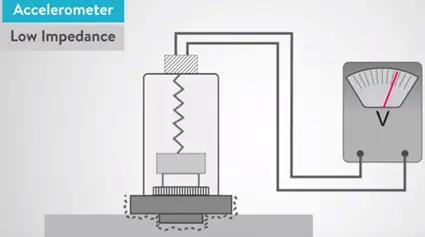

Low impedance

The low impedance accelerometer is a front end as well as built in micro circuit into resistor converts that change into low impedance voltage. This type of accelerometer is easily interfaces with standard instrumentation which is commonly used in industries.

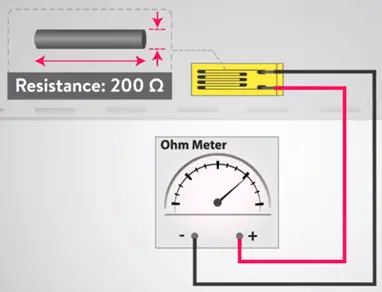

Strain gauge

The strain gauge is just like a sound strain gauge measurement. The strain on the machine component stain gauge sensors whose resistance varies with the force it converts force, pressure, tension, weight etc. into an electrical resistance which it can be measured.

When an external force is applied on stationary object the stress or strain will be results.

When a strain applied to any metallic wire the length of the wire increases and diameter decreases. This increase length and decrease in diameter will change the resistance of the wire which will give measurement of the strain on a machine component.

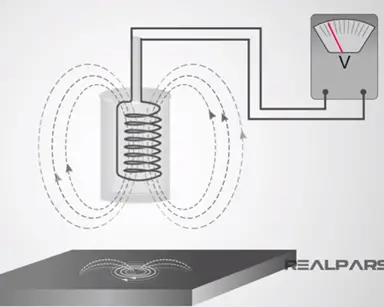

Eddy current or capacitive displacement sensor

Eddy current sensor is a non-contact device they measure the position and change the position of a conductive component. Theses sensors operate magnetic fields the sensor has a probe which creates an alternating current at the tip of the probe, alternating current creates the small current in the component we are monitoring is called eddy currents. The sensors monitors the interaction of these two magnetic fields as the fields interaction changes the sensor will produce a voltage proportional to change of two fields, when we using eddy current sensors is important is three times larger than the sensor diameter for normal operation otherwise calibration is required.

Selection of sensors

While choosing a vibration sensor for application it is important to look facts such as range, accuracy, environmental condition, shape of the measuring surface.

Accelerometer

Out of these sensors the accelerometer is the common because it has a good range of frequency in measuring slow and fast applications; along with the frequency accelerometer is priced affordable and durable. They are mounted directly to the machine which is common for vibration sensors.

Eddy current or capacitive sensors

Eddy current has medium accuracy and not optimal for high resolution application, they are very durable for dirty environments. It is also like a accelerometer it is directly mounted in the machine.

Strain gauge

Strain gauge is versatile and accurate and it is suitable for hazardous environment, unfortunately they have hard to install correctly and for proper data application it needs the amplifier.