PRESSURE SWITCH AND CALIBRATION

The pressure switch is mainly used in the industries for the turn ON and OFF for electrical circuit. The pressure switches are used for applications such to start motors, solenoid valves etc.

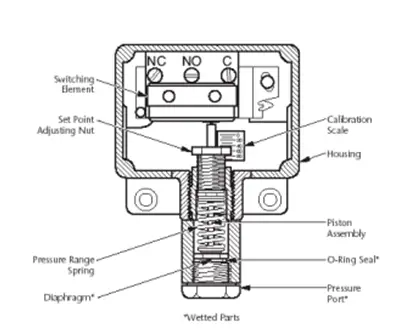

The diaphragm is used for to control the pressure when its applied.

The pressure range spring is used for to set the operating pressure and set point adjusting nut is used for to set the pressure to activate the relay contact.

Calibration scale is to see the manually for setting the pressure.

The switching element is for to change over the contact the NC and NO.

In pressure switches normally have two contacts normally open (NO) and normally close (NC)

When the pressure is applied it enters into diaphragm the diaphram gets pressed and touches to pressure spring when pressure spring reches its desired set point pressure it will contact to switching element according to set point pressure high or low the contact act and activate the supply will go to motors, solenoid valves etc.

The contacts are normally in open switch remains open until the pressure rises above the set point. The sensing element makes contact to closed position the contacts open again when the pressure falls below the set point. The contacts in closed switch remain closed until the pressure rises above the set point . then the contacts open and open until the pressure drops below the set point.

When the one contact is open and other contact will be closed this is the normal condition of the pressure switch.

Uses of pressure switch

The pressure swicth is used for to protect the limiting pressures for the safety of the machineries example turbine

It also used for controlling of oil flows at limited pressure and controlling of pressures in compressor etc.

Calibration procedure of pressure switch

Step 1 : Connect the hand pump in the Pressure calibrator with the suitable adaptors.

Step 2: Connect the test pressure switch in the Hand pump through the PU tube.

Step 3: Select the selector switch in the hand pump for selecting pressure.

Step 4 : Switch ON the Pressure calibrator and select the unit of kg/cm and press the zero button make the zero.

Step 5: Give the give pressure through the hand pump

Step 6: Give the initial pressure through the hand pump to the pressure switch and check the NO/NC acting if points acts remove switch, If not acts increase the spring tension again if not acts replace new switch

Step 7: After completion of the pressure switch slowly decrease the pressure in the hand pump through the Vernier setup.