Starting methods of synchronous motor:

In our last article, we have studied why the synchronous motor is not self-starting since the net torque developed by the motor is zero. Now you get a question about, how to start a synchronous motor to reach synchronous speed? There are six starting methods of the synchronous motor are employed. Let us have a look one by one.

Starting Methods of synchronous motor:

- Reduced frequency method

- External driver Method

- Using Induction motor

- Using a DC machine

- Using damper winding

- Slip ring assembly

Variable Frequency or reduced frequency Method:

As you know, the synchronous speed is directly proportional to the supply frequency. By reducing the supply frequency, we can reduce the speed of the synchronous motor’s stator magnetic fields.

Hence by controlling the speed of the stator magnetic field, you can lock the stator and rotor magnet easily. This is the basic concept behind the variable frequency starting method.

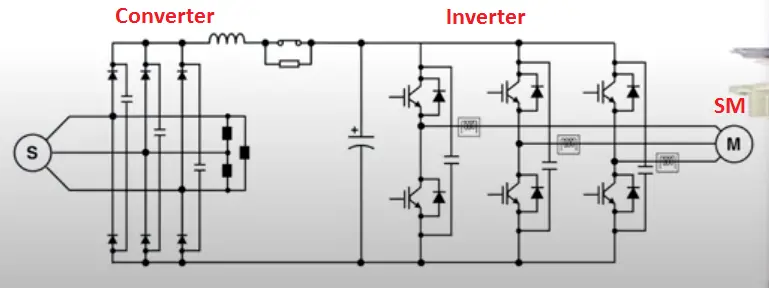

Generally, variable frequency drives are used to reduce the supply frequency. VFD consists of rectifier/converter and inverter module. These modules can be used to convert the constant input frequency to any desired output frequency from a fraction to full rated frequency.

Also, such VFD units are also used to control the motor’s speed to a very low value for starting, and then raise it up to the desired operating speed for normal running.

While operating a synchronous motor lower than the rated speed, its back emf is generated in the motor also lower than the normal.

If the back emf is reduced in magnitude, then the applied voltage to the motor must be reduced as well in order to keep the stator current at safe levels. That’s why VFDs are designed to reduce the voltage along with its frequency. It means V/F ratio must be constant at any instant.

How Vfd works

Motor starting with the external driver circuits:

The second way to starting of a synchronous motor is by coupling an external driver which help the synchronous motor to reach the full speed.

Here the motor is connected like a generator in the power system. Once the motor is reached to full speed starting motor will be detached from the synchronous motor.

The synchronous machine can be paralleled with its power system as a generator, and the starting motor can be detached from the shaft of the machine.

Once the stating motor is disconnected means, the speed of the SM starts to fall down, the rotor magnetic field Br falls behind stator rotating magnetic field Bs. And the synchronous machine starts to act as a motor.

Actually we have two kinds of starting motors such as

-

An induction motor or pony motor

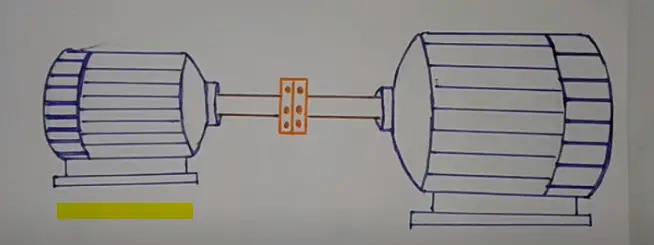

Here left side motor indicate – induction motor and right side motor indicate synchronous motor.

A small (also called as a pony) Ac induction motor will be connected with the synchronous motor. The synchronous motor runs along with the Induction motor initially. If the motor reaches to rated RPM, the DC excitation will be turned on. If the synchronisms is established the induction motor will be decoupled from the synchronous motor.

-

DC machine:

The higher rating synchronous motor will be started with the DC machines only. Initially the DC machine act as a motor which drives the synchronous motor from 0 speed to rated speed. Hence the synchronism will be established. At the same time, the DC machine acts as a DC exciter and which provide DC supply to the synchronous motor’s rotor.

Using Damper winding:

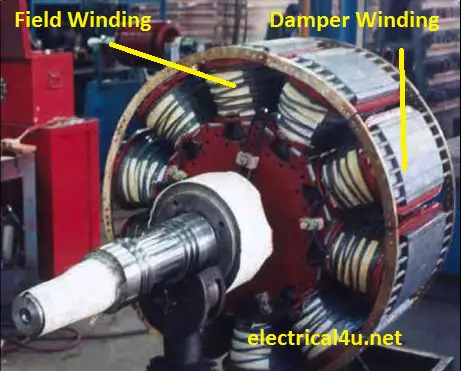

The lower rating synchronous motor’s rotor field winding is designed along with the separate copper bars and whose end is short-circuited with the help of end rings. This additional winding is called damper winding and it is the most popular methods of starting synchronous motor.

Consider you turn on the three-phase voltage to the stator of the synchronous motor, the motor starts rotating at sub synchronous speed. Here synchronous act as an induction motor.

If you turned on the field supply means, the stator pulls the rotor to its synchronous speed and the rotor start rotating at synchronous speed.

During synchronous speed, the relative motor between the stator rotating magnetic field and damper winding is zero, hence the synchronous motor cannot produce induced emf in the damper winding.

The damper winding is active at the time of stating only, after reaching synchronous speed, the damper winding act as dummy winding.

The major disadvantage of this starting method of a synchronous motor is, the motor draws high starting current like an induction motor. Hence different types of starting method such as star-delta starter, autotransformer starter need to be employed.

Slip ring Induction motor:

In above starting method, the damper winding/induction motor does not provide the high starting torque to the synchronous motor, that’s why slip ring assembly is introduced in the field winding of the synchronous motor’s rotor.

Here the end winding of the damper bar will be connected to the resistance circuit. The rotor acts as a slip ring rotors of the induction motor. as you know the rotor resistance is directly proportional to the starting torque.

At starting high resistance circuit will be added and the resistance will be cut off with respect to the speed. When the motor reaches to subsynchronous speed, the resistance across the rotor will be reduced.

You have to turn on the DC excitation at sub synchronous speed, then the stator pulls the rotor to synchronous speed. The motor rotates at synchronous speed continuously.

By this method of starting, we can achieve high starting torque.

However, you have to follow some certain procedure to avoid electrical and mechanical damage to the motor.

How to start synchronous motor:

Step1: Turn on the input three-phase voltage to the stator and the same produce RMF at synchronous speed.

Step3: Start the external driver motors with the direction of the rotating magnetic field. Run the driver circuit to reach the rated speed.

Step2: Now turn on the DC excitation to the rotor. Now you see, the stator pulls the rotor to synchronous speed. The motor runs at synchronous speed.

Step4: Stop the driver circuit.

Frequently Asked question:

What are the various methods of making synchronous motors self-starting?

By using Damper winding method, you can start the synchronous motor start itself.

Significance of damper winding in synchronous motor starting:

Damper bars balance the extra torque produced by the rotor during the change in input frequency. It helps to boost the speed when the motor speed is slow, as well as it uses to reduce the speed when the rotor speed is high.

It damps out the extra torque produce by the rotor, that is by it is called damper winding.

Does the synchronous motor acts as a synchronous generator?

Yes, in earlier days, the motor was driven by the external turbine assembly along with the constant speed application i.e feedwater pumps. when you pass steam to the turbine, which rotates the synchronous motor.

While exciting the field winding we can reverse the power. The current flow starts from the motor to grid. Here the motor act as a generator.

At the same time while the failure of receiving steam to the turbine, the synchronous machine act as motor and we can run the constant speed application continuously.

Does synchronous motor has starting torque?

No, It is zero torque. Since the net torque developed in the complete one electrical cycle is zero.

Starting Methods of Synchronous motor [Video]:

The external driver circuit is applied to pickup the synchronous speed of the motor.

![Why Synchronous Motor is Not Self Starting [Simple Explanation]](https://electrical4u.net/wp-content/uploads/2020/06/Synchronous-motor-is-not-self-starting-218x150.png)