Submersible Pump Nameplate Details:

Submersible pumps are used to drain the water or pumping the water from the underground. The main advantage of submersible pumps is, it does not require any civil foundation arrangement like conventional pumps. That’s why submersible pumps are mostly used. Two different types of submersible pumps are generally manufactured;

- one is open well submersible pumps (used in all open well)

- Second one is bore well submersible pumps (mainly used in domestic bore wells)

In this article, we are going to see, How to read submersible pump nameplate details.

Working Principle of submersible pumps:

Electric submersible pumps are multistage centrifugal pumps operating in a vertical position. Liquids, accelerated by the impeller, lose their kinetic energy in the diffuser where a conversion of kinetic to pressure energy takes place. This is the main operational mechanism of radial and mixed flow pumps.

Read Submersible pump nameplate details:

Open well submersible pump set:

It means the type of submersible pump. It can be used to pumping the water from the visible water body such as well, pond, lake etc. While purchasing a submersible pump you should mention the type of application. The cost and design is depending upon the types and application.

[wp_ad_camp_2]

Electrical details:

1ph: 1ph means the motor runs on single phase power supply, the motor inside the submersible pump can be run by applying single phase power supply.

220V: This is The maximum voltage applied across motor terminal. The voltage should not be exceeded above 230Volts.

2800 RPM: RPM means Revolution Per Minute. It means a motor or a rotating device that rotates 2800 times for one minutes. It says about the speed of the motor-pump set. The high speed pumps produce higher water flow.

Frequency 50 Hz: The Input frequency of the power supply. The 50 Hz pump cannot be operated on 60 Hz.

Duty S1: It means continues duty, the motor can be operated 24X7 without rest throughout the year.

WET Type: Wet Type in Submersible pump means, the outer body of the pump should have immersed in water. Because the main cooling agent of these motors are water only since the motor and the bearing should be always filled with the water.

Important Note: Never recommended to run a motor without water.

Model No: NIO10.: It means each manufacture have their own design of pumps. Since, they name their pump with the model number, in order to update their pumps; while updating, the consumer can be easily understanding the key difference between old model and the new model.

KW/HP: 0.75/1: It means the motor consumption per hour, the motor consumes 0.75 kw per hour. If you run a motor on full load, the motor eats 0.75 units for one hour.

Maximum Current:

It is the Maximum allowable current to the stator winding of the motor. The motor protection has to be arranged for the maximum allowable current of the motor. here the protection should be designed for 10 Ampere current.

Stage 1: The stage says about the number of impeller are used. The multistage pump has more than one impeller. The higher number of impeller pumps produce the higher water flow with high discharge. But mostly in rural area, the lower stage pumps are recommended for cost effect.

[wp_ad_camp_2]

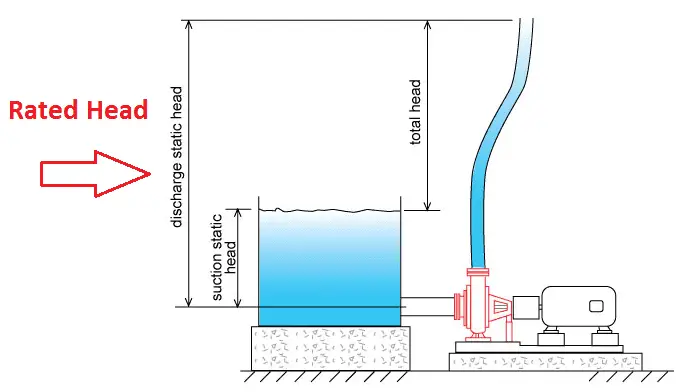

Rated Head: 21 M

Rated head means the maximum height that, pump can deliver its full output. Here 21 Meter means, the pump delivers full output of rated discharge (1.4lbs) for 21 M from the pump impeller center. Refer the figure…

Rated Discharge: 1.4 Lps

Lps is a short term of liter per second. The pump can deliver or discharge the maximum output of 1.4 liter in one second.

Head range: 17- 22M: It means the minimum and maximum range of the pump head

Delivery Size: 25 mm: The output from the pump can be taken by connecting 25mm size of the pipe

Connection CSR: CSR a type of terminal pipe connection which means the threads will come on the pipe surface. Refer the figure.

S.No and Manufacturer details are mentions for feature reference and it an type of advertisement.