Hydraulic Pumps:

The hydraulic pump is the mechanical power is converted into the hydraulic energy. The hydraulic pumps are used in the hydraulic drive systems, its hydrostatic or the hydro dynamics.

The hydrostatic system is generate the flow with the power to over come the pressure generate by the load at the pump out let area.

The hydraulic pumps are active the vacuum is created at the pump inlet area, the forces are created in the inlet area liquids from the reservoir in the in let line to the pump, and the mechanical action is happen the liquids are deliver to the pump outlet and forces also acting into this hydraulic system.

The hydro static pumps are mostly working in the pascal’s law. The plenty of types of hydraulic pumps are the rotary vane pumps, screw pumps, bent axis pumps, inline axial piston pumps, radial piston pumps.

The flow is calculated in the hydraulic pumps of this formula Q= n.Vstroke. ηvol here Q is the flow in m3/s, n is the stroke frequency in Hz, and Vstroke is the stroked volume in m3. And the ηvol is the volumetric efficiency.

The power of the hydraulic pump is calculated to this formula P= n. Vstroke . ∆p / ηmech. Here power in watts, n is stroke efficiency in Hz, Vstrike is the stroked volume in m3 and the ∆p is the pressure difference in the pump in pascal. Ηmech,hydro is the mechanical and hydraulic efficiency.

The mechanical efficiency is calculated in the hydraulic pumps are the

nmech= Ttheoretical / Tactual. 100%. Here, the nmech is the mechanical pump efficiency percentage, Ttheoretical is the theoretical torque to drive and Tactual is the actual torque to drive.

The hydraulic pump efficiency is calculated as the nhydr= Qactual / Qtheoretical. 100%.

Now we are going to see here the types of hydraulic pumps, its cost, works, and its photos.

Types of hydraulic Pumps:

Rotary Vane pumps:

The rotary vane pump is the positive displacement pump and its have the vanes are mounted to the rotor, its rotates inside the cavity. This vanes length is vary from the pump to pump and its touch on the walls at the pump rotates.

The critical element of the rotary vane pumps are the vanes are designed and its pushed into the contact with the pump housing and the vane tips design also is too critical.

The lip design in the vane pumps are the main thing to give the tight seal between the inside housing and the vane. Its minimize the wear and metal to metal contact.

The spring loaded vanes are used in this type of pumps to force the vanes to rotates at the center of the housing, this vanes are loaded hydro dynamically.

The rotary vane pumps are sales in the market is the 5200 to 1,35,000 rupees. This rotary vane pumps are mostly used in the automobiles, super charging, power steering, air conditioning and automatic transmission system.

The flow rate of the rotary vane pumps are the 30 to 2200 liter per hour at the pressure is up to 18 bar. The actual life of the rotary vane pumps are the 10 years. The mechanical efficiency is to give the rotary vane pumps are the 80 to 85%,.

Screw pumps:

The screw pumps are the fixed displacement pumps and its have the two Archimedes screws that is mesh with the same chamber. The screw pumps are used for low pressure and high flow situation are the 100 bars pressure and 10000 kpa flow.

The screw pumps are mostly used in the board ships, because of the board ships have the constant pressure hydraulic system, is passes through the whole ships and its control the ball valves.

This system is used to help the steering gear system and other working system in the ships. The sound level of the screw pumps are in very low and its efficiency is also slightly low.

The hydraulic reaction force of the screw pumps are transmitted in the axial direction and its opposed to the direction of flow. This is one of the draw backs of the screw pumps.

This problems are easily over come are the thrust bearing beneath is fixed on the each rotor of the screw pumps and the hydraulic balance is created by directing the hydraulic force to a piston and its under the rotor.

The plenty of types of screw pumps are available in the market is the single end screw pumps, double end, single rotor, multi rotor timed, multi rotor untimed screw pumps.

The screw pumps are give the efficiency are the 60 to 80% of its performance. The flow rate capacity of the screw pumps are the 220 gpm that is the 833 liter per minute to 11,000 gpm that is the 41,635 liter per minute.

The screw pumps are used in the fuel injection system, oil burners, boosting, hydraulics systems, lubrication, circulating, feed and pump high pressure viscous fluids in offshore and marine installation.

The flood control, chemical movement, air conditioning system, water and gas supply industries are mostly used to this screw pumps.

The screw pumps are sales in the market is the 14,000 to 30,000 rupees.

Bent axial pumps:

The bent axial pumps are called as the axial piston pumps and its motors are working in the bent axis principle and its have the fixed or the adjustable displacements design of this bent axial pumps.

The bent axial pumps are working in the thoma principle with the maximum of the 25 degree angle and the wahlmark principle with the maximum of the 40 degrees angles are the

spherical shaped pistons, piston rod, piston rings in between the drive shaft center and pistons.

The bent axial pumps ate give the huge amount of efficiency and its have the largest displacements are the one liter per revolution is necessary for the two liter swept volume pump to be designed.

The oil flow can be adjusted care fully in the variable displacements pumps are used in the bent axial setup. The bent axial pumps are working in long hours in the 350 to 420 bars pressure continuously.

The bent axial pumps are give the mechanical efficiency is the 80 to 90%. The automotive air conditioning compressor and the heavy duty industry is mostly used in the bent axial hydraulic pumps.

The bent axial hydraulic pumps cost in the market is the 75,000 rupees.

Inline axial piston pumps:

The inline axial piston pumps are the variable displacement pumps, its fluid discharge per revolution and system pressure are control this factors are the load requirements, maximum pressure cut off settings, horse power, ratio control, electro proportional systems, electrical signals.

This factors are increase the inline axial piston pumps power saving is high is compared to the other constant flow pumps.

The prime mover, diesel, electric motor rotational speed was constant and the inline axial piston pump fluid flow is non constant. The inline axial piston pumps the pistons and cylinders are rotate around the center of the longitudinal axis.

The inline axial piston pumps efficiency is 92%. The inline axial piston pumps are give the higher pressure and high horse power and precision control, because of the more number of pistons are rotating with in a cylinder block. So its give the high horse power.

Now a days the lots of industries are use in this inline axial piston pumps. The electro hydrostatic actuators and aero space industries, agricultural machinery, mining machinery, construction industries are mostly use this inline axial piston pumps.

The flow rate of the inline axial piston pumps are the 100 liter per minute and its maximum pressure is the 1000 bars and its cost in the market is the 4500 to 55,000 rupees.

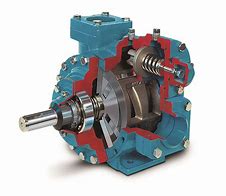

Radial piston pump:

The radial piston pump is the hydraulic pump and its working pistons are extend in the radial direction symmetrically around the drive shaft. The stroke of the each piston is count in the radial piston pumps are the eccentric drive shaft or the external eccentric tappet.

The pumping piston from the inside pistons are the inside impinged radial piston pumps, and the out side piston of the radial piston pumps are the outside impinged radial piston pumps.

The piston starts in the inner dead center with the suction process, after the 180 degree rotation angle of the piston is filled with the moved medium.

The radial piston pump is mostly used in the machine tools, high pressure units, test rigs, automotive sectors, plastic industries, wind energy industry, food and beverage production industry, pharmacy, heating and cooling places.

The hydraulic fluids are used to this radial piston pumps are the mineral oil, bio degradable oil, water glycol, synthetic ester.

The radial piston pumps are give the higher pressure is up to 1000 bar range. The noise level of the radial piston pump is very low. The radial piston pumps are give very high efficiency of the 98%.

The operating pressure of the radial piston pump is the 400 to 700 bar. The radial piston pumps are mostly apply in the move liquids and compress gases situation.

The radial piston pump is sales in the market is the 7000 to 4,55,000 rupees and its life is the average of the 16 to 20 years.

Types of Hydraulic pump: