HART PROTOCOL

The control loop technology is been used for analog sensor for past decades to transmit important process data to control system. Whether that system in DCS or PLC or single loop controller.

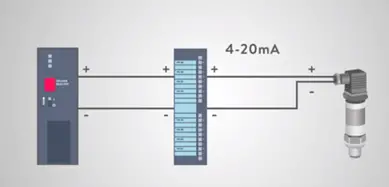

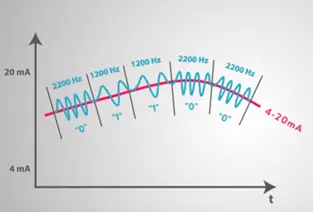

Control loop data transmission is simple and cost effective on small amount of current 4- 20 mA is exact over the single pair of wires for each current loop sensor are 2 Amp, 24 V dc power supply can drive dozens of sensors.

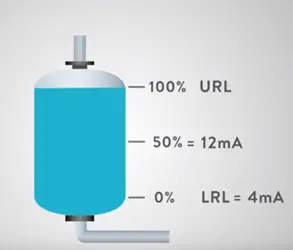

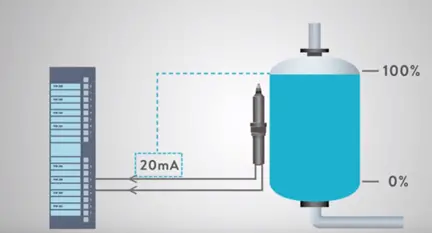

For current loop analog sensor is lowest measurable process value is called the lower range limit ( LRL ). Analog output sensor 4 mA is at 0 % reading. The highest measurable process value is called upper range limit ( URL ). Analog sensor output is at 100 %. Many analog sensors such as pressure, temperature sensor, flow and analytical sensors all are required single pair wire for transmit process variable or measured variable to control system.

The positive features for analog sensor and transmitter signals can be carried at a longest distance in single pair of cables without a signal loss. Current signal can be transmitted up to 1000 meters with 18 gauge wires with no applicable signal loss.

The lossless the 4- 20 mA current loop signal is provide a basic level of diagnostics since 0 % equals the 4 mA signal and broken wire brake the circuit 0 mA will be sensed. This live zero features is zero percent is equal to greater than the value of 0 mA allows the control system to detects the broken wire at 0 mA.

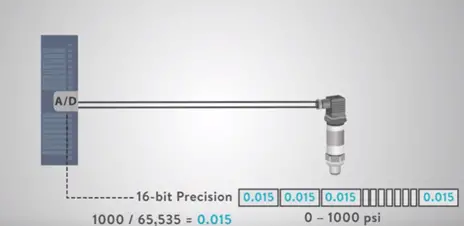

The analog signal can be allow to send one value over single pair of wire to control system and granular id or precision of data is limited by the type of analog to digital controller ( A/D converter ) used by control system electronics with A/D converter 16 bit precision with the port of range of analog sensor 0 – 65535 incremental. This means 0 to 1000 psi pressure sensor the granular id of the signal value 1000/65535 = 0.015 psi. this level pf precision is sufficient for most applications.

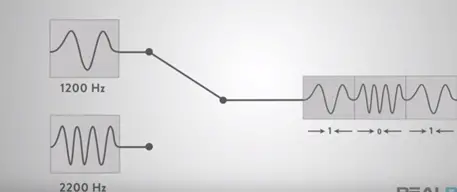

In late 1970 bells lab invented bell 202 modern standard. In 1980 bell 202 standard was adapted the communications standard sub-see oil production control system. Bell 202 specifies margalesties method known audio frequency shift keying ( AFSK) to encountered and transferred digital data at a rate of 1200 Hz bit per second. Half duplex transmission is only one directional at a time. Basically provides a continuous signal as a AC sine wave this shifts its frequency 1200 Hz indicating a binary value 1 to 2200 Hz indicating binary value 0.

If we super impose a bell 202 signal on a top a analog signal standard telephone line signal we gain the ability to send the data and analog data at same time on a same pair of wires. This used to transmit caller telephone number, along with the voice call. This feature is known as caller Id.

The super imposed bell 202 signal on a top of standard analog sensor line signal. We gain to ability to send different data and analog data at the same time on a same pair of wires. This is hart communication.

With hart we can send analog data such as measured value, process variable along with the digitally transmitted data such as tag name, calibration settings etc . this would be the real pro-activity in enchantment in the process plant, because hart enable sensor regains only a single pair of wires for communication to upgrade an existing non- hart sensors loop to hart enabled loop number wiring changes required.

Off-course both the sensor and analog input card controller heel the support of hart. The hart is build in most of the analog sensor hart enabled input cards are available DCS and PLC manufactures.

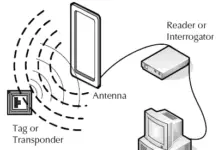

HART- Highway Addressable Remote Transducer

It is simply means that small network can be formed with 63 HART devices. Each having address or node because sensor can be mostly accessing the hart really does save it to all. Highway or network sensor also called as transducer that has an address so it can access remotely and directly.

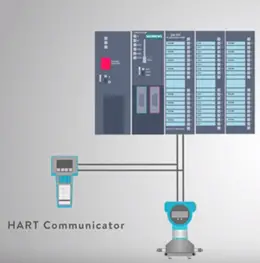

In this diagram we have seen hart sensor is connected to PLC by input card. We can access data remotely using the hart communicates protocol from the PLC programming software that means we do not have to location to access its data.

We can configure calibrate and retrieve diagnostics data from the control room or other location whether the hart data is accessible. Data from the hart sensor must be request by the master node. Which control the all conversation in the loop. The master node is typically the DCS or PLC analog input card that the sensor is wired. The each message from the master is request type such as process value, new value, URL or LRL etc.

By using hand held configure device often called hart communicator. Sensor data can be accessed where the opportunity exists to connect the hand held device through loop wires it can be any junction box, marshaling panel or in the sensor itself.

Network hart devices most control system application is not practiced because its limited speed and multipalant topology we generally signed on node sensor to each hart signal. Fortunately hart allows to master nodes so that the control system and hand held communicator can be both connected in loop and communicate the device at same time. With hart analog 4 – 20 mA signal and digital hart protocol are both available in control system.

If the sensor loop is upgraded from analog only the analog plus hart the control system programming and configuring the measurement value can stay the same.

How to determine phase angel for vector shift relay? which is deployed into power plant,please describe along with formula respective values of whole quantities which would have to be used in formula.