How to Run Three Phase Motor On Single Phase Power supply:

Nowadays using the number of electrical motors are increasing like anything. The main reason is that other than electrical energy, all the energy is a much costlier example: diesel. For all our agriculture line we use the three-phase power supply. In India for agriculture purpose government offers 12 hours’ free power supply.

The remaining 12 hours the electricity board cut the power supply, which means they remove one phase through GOS (Gang operating switches). At the same time, 12hours is not enough to pour the water into our agriculture land.

So that we need to run the same three-phase motor on two available phases. In this, article we are going to see how to run the three-phase motor on single phase. Let start.

Generally, this action can be done by installing static phase converters. Static phase converters are a startup device for three-phase motors on single-phase power. The static phase converter does not actually produce three-phase power continuously.

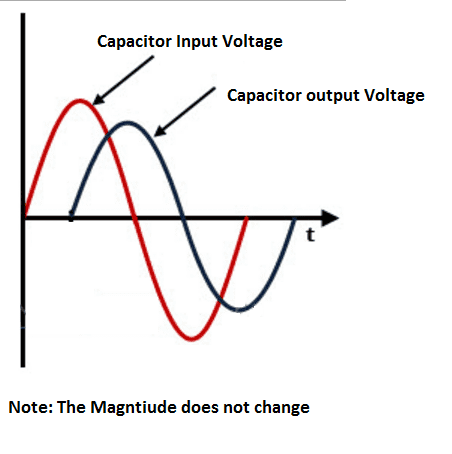

Instead of that, it generates A phase shift through a capacitor which allows the voltage to be displaced in time from its parent voltage. The result is a voltage distinct from the 2 single-phase lines. If the capacitor produces sufficient electrical current, the motor will operate.

Once the three-phase motor has started means, the static phase converter circuitry disconnects itself. Here the only one fact is the motor continuously runs on single phase with two winding receives active power, so that the net output of the motor will be reduced typically 2/3rd of its rated capacity.

Example if you are planning to operate a 5 HP three-phase motor in Single phase, then the total output power of the motor will be reduced to 3.3HP. If you push further loads on the same motor, the motor’s winding takes high current. To avoid this you can select a motor with one step higher range.

Also see:

- Why Battery Cannot Store AC voltage

- Why Capacitor and Inductor are used in Filtering Circuit

- Why Capacitor Has Leading Power Factor

- Why capacitor is required for Single phase motor

- Single Phase Preventer Working Principle | Induction Motor Protection

Capacitor design for Three Phase Motor On Single Phase Power supply:

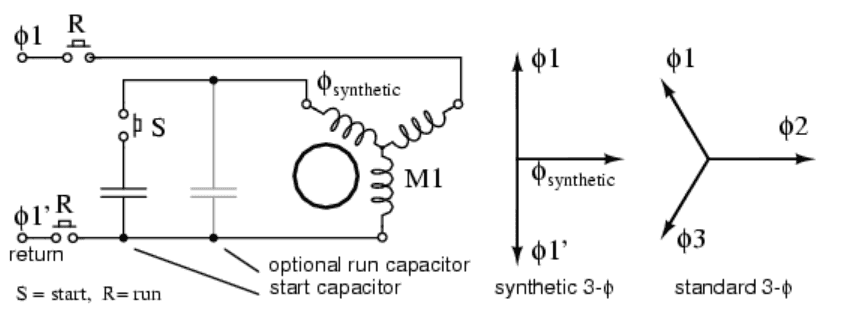

As the property of induction motor, which takes high starting current (why?)(4 to 6 times of its full load current) so that we need a high rating of capacitor for few seconds to start the motor quickly. A static phase converter is consisting of two number of capacitors. One is a start capacitor and another one is running capacitors.

Start capacitor requires only to starts up the motor and running capacitor will stand on the circuit. Moreover, adjustment of these capacitors to equalize the currents as measured in the three phases results in the most efficient machine.

The start capacitor should be 4 to 5 times than running capacitors to match the induction motor high starting current.

Start capacitor = 50-100µF/HP. Run capacitors = 12-16µF/HP.

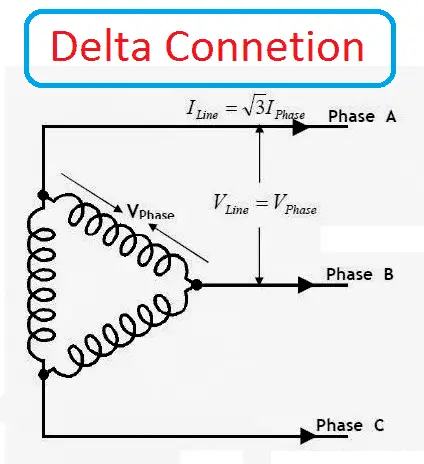

Here The capacitor supplies a synthetic phase approximately midway ∠90 deg between the ∠180 deg single-phase power source terminals for starting. While running, the motor generates approximately standard 3-φ, as shown in Figure below.

Note: The Motor should be connected in delta connection, as the motor single winding receives full voltage. So if you are planning to run a three-phase motor on single phase, the recommended connection is delta.

Limitation of Static phase converters:

- The output power has limited to 2/3rd of the designed power

- Not suitable for continues running motor, it can be used for temporary purposes

- It reduces the motor life span, because of the continues loading of two windings on a single phase.

Run Three Phase Motor On Single Phase Power Supply:

Also, see:

- Cheap DOL starter – DCS/Remote/Local Start/Stop

- How To Make A Electrical Starter and Power Circuit

- How to Repair Electrical Wire Insulation Failure

- How to Understand Motor Nameplate Details-ND 280 M/S/L

- How VFD Saves Power & Basic Concept of VFD

- Identification of Motor Frame Size 132M & Motor EFF class EFF1 EFF2

- Star Delta starter wiring diagram with Full Explanation

- Why Star delta starters are preferred for higher HP motor

This blog will be very helpful for electrical engineering students

This is very useful and helpful blog for me. Thanks.